| Microgravity

Experiments |  |

-

In microgravity, physical phenomena which never appear on

Earth may be clarified and the material constants may be measured more precisely.

This is because the space environment is totally different from the Earth.

For example, there is no liquid convection induced by the difference of

density of two materials, and two different materials with differing densities

can easily be mixed. In one space utilization application, new semiconductor,

composite material or new protein crystal are expected to be processed in

space. Industrial applications are urgently being sought.

Diffusion of Liquid metals and Alloys

Dr.Toshio Itami, Hokkaido University

1.Objectives of the Experiments

- Although the diffusion coefficient in a liquid state of pure metals and

alloys is industrially and scientifically important, few tests have been

performed with high accuracy on the ground because the effects of convection

are not negligible due to samples' high density and low viscosity. The Self

diffusion coefficient of tin, an easily handled metal, will be measured

using a stable isotope as a "tracer" of atomic transport. Tin

has a comparatively low melting point (231degrees), allowing a wide range

of temperature and precise examinations of temperature dependence. It is

reported from the previous experiment performed on orbit that diffusion

coefficient of tin was 20 persent less than that measured on the ground

and the temperature coefficient is also different. In MSL-1, the temperature

range is widened and new technology is introduced in order to perform experiments

with higher accuracy. Results from these experiments should help us better

understand the mechanism of diffusion process in liquid metal.

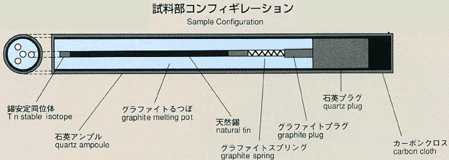

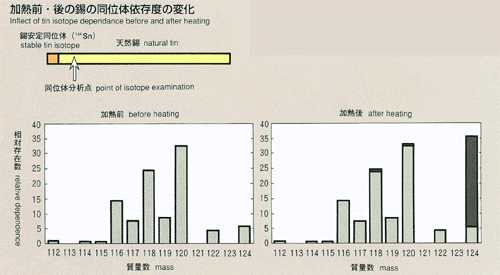

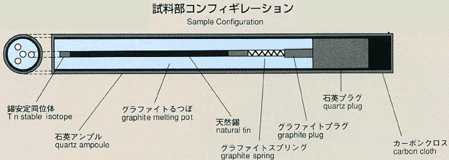

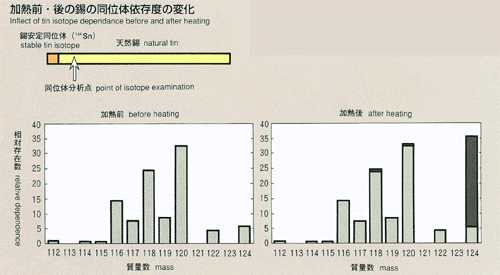

2.Method of Microgravity Experiment

- The most common method for measuring the diffusion coefficient, called

the long capillary method, is introduced for this experiment. With this

method the diffusion coefficient may be measured by examining time-dependent

variations of concentration of tracer which is initially placed in a capillary

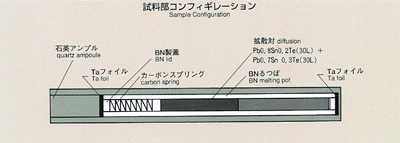

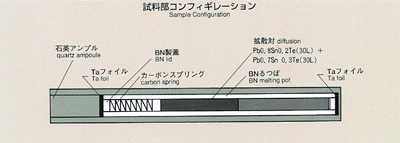

shaped sample. For MSL-1, a rod-shaped sample of tin (2mm diamiter, 60mm

long) with tin isotope (124Sn) placed on one end as a tracer is used. A

melting pot with four cylindrical holes, each with diameter of 2mm and length

of 80mm, made of graphite will be used. Also, a graphite lid and spring

are implemented to eliminate the existence of free surface in response to

the volume change of sample during heating, fusion, cooling and solidification

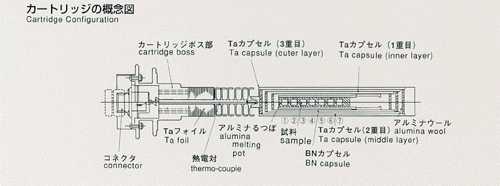

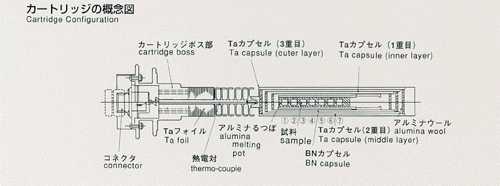

processes. To prevent oxidation of the sample, the melting pot is double

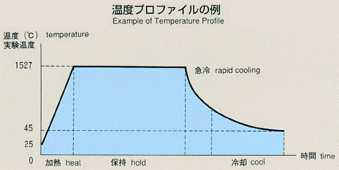

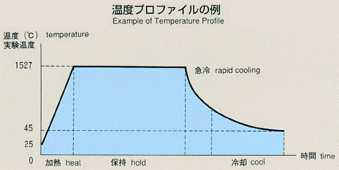

contained in cylindrical quartz and tantalum. After the sample is heated

and melted, the temperature will be held, allowing the diffusion to proceed

for a certain time. The sample will be cooled down and be solidified. The

diffusion coefficient will be determined by analyzing the isotope density

of the sample. Because the theoretical diffusion model is based on a constant

temperature, the diffusion which occurs during the heating and cooling process

introduces some errors into calculations. Rapid heating and cooling will

minimize these effects, and an accurate diffusion coefficient will be determined,

and compared with results from the Shear Cell Method.

Diffusion in Liquid Lead-Tin-Telluride Ms.Misako Uchida, Ishikawajima-Harima

Heavy Industries

Ms.Misako Uchida, Ishikawajima-Harima Heavy Industries

1.0bjectives

- Diffusion coefficient is of great importance in manufacturing high-quality,

homogeneous crystals for semiconductors and must be considered to produce

quality devices, especially for combined semiconductors. In MSL-1, a combined

semiconductor, lead-tin-telluride, generally used for infrared semiconductor

lasers or exposures, will be provided and the diffusion coefficient of lead

and tin will be measured. The results should be of great use for determining

the best conditions to form a homogeneous crystal. From basic science aspects,

multiple atoms in molten combined semiconductors travel under influence

of the chemical bonding between them. An accurate diffusion coefficient

measured in space should help us better understand the mechanism of diffusion

in molten semiconductors.

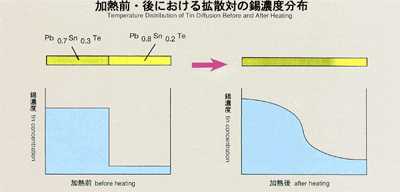

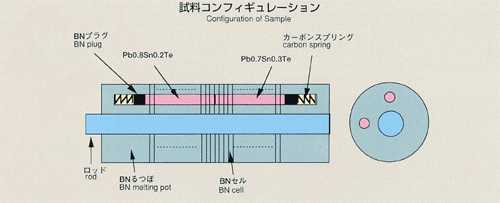

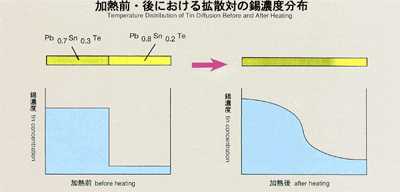

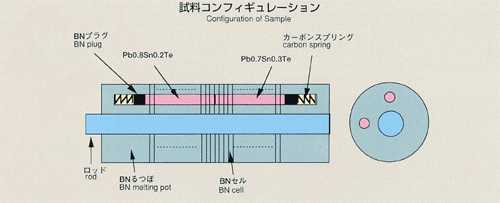

2.Method

- The most common method for measuring the diffusion coefficient, the long-capillary

method, is introduced for this experiment. With this method, the diffusion

coefficient may be measured by examining time-dependent variations of concentration

of tracer which is initially placed in a capillary-shaped sample. For MSL-1,

lead-tin-telluride formed of two different composition (Pb0.8Sn0.2Te and

Pb0.7Sn0.3Te) is used as a sample. Lead or tin may be used as a tracer.

A graphite melting pot with cylindrical holes, 2mm diameter, 80mm long,

will be used. Also, a graphite lid and spring are implemented to eliminate

the free surface in response to the sample volume change during heating,

fusion, cooling and solidification process. To prevent oxidation of the

sample, the melting pot is double-contained by a cylindrical quartz and

tantalum. After the sample is heated and melted, the temperature will be

held, allowing the diffusion to proceed for a certain time. The sample will

then be cooled down and solidified. The diffusion coefficient will be determined

by analyzing the isotope density of the sample. Because the theoretical

diffusion model is based on a constant temperature, the diffusion which

occurs during heating and cooling introduces some calculation errors. Rapid

heating and cooling will minimize these effects. An accurate diffusion coefficient

will then be determined, and compared with results from the Shear Cell Method.

Impurity Diffusion in Ionic Melts

Dr. Tsutomu Yamamura,

Tohoku University

1.Objectives

- Ionic melts is a molten chloride, consisting of an anion and a cation.

Studying diffusion in ionic melts should provide us with more information

and help us better understand the nature of electrical interactions. In

this research, the diffusion coefficient of ionic silver in ionic melts

(LiCl-KCl) will be measured by chronopotentiometry, a commonly used method.

This method requires only a brief period, and should be free of gravity-induced

convection. However, those experiments done on the ground have shown some

enormous range of results, implying the effect of gravity. In MSL-1, in

a microgravity environment that generates little gravity-induced convection,

an accurate diffusion coefficient will be measured in real time.

2.Method

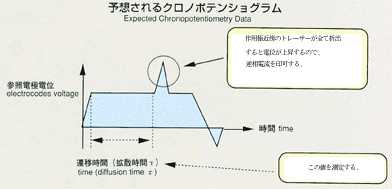

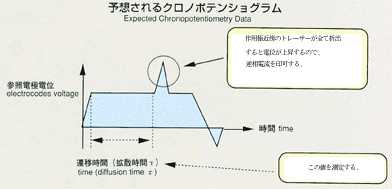

- Applying a voltage between electrodes, inserted in ionic melts, induces

current. The degree of voltage or current depends on the numbers of ions,

travelling towards electrodes. Under certain condition, electric current

may be induced only by ionic diffusion.This will be suitable for measurement

by the electrochemical method. With chronopotentiometry, an appropriate

current is applied between electrodes. The diffusion difference coefficient

will be determined by analyzing the time variation of voltage difference

between electrodes. This voltage difference will maintain a constant value

in response to only diffusion of ions, which may be correlated by the following

equation. The diffusion coefficient will be calculated by inserting transfer

into the equation. The accuracy may be improved by applying low current

and by extending the transfer time. While ground experiments use higher

current and measure voltage faster to prevent the effect of gravity, space

experiments can use lower current in various levels and measure various

transfer times in order to obtain a diffusion coefficient with high accuracy.

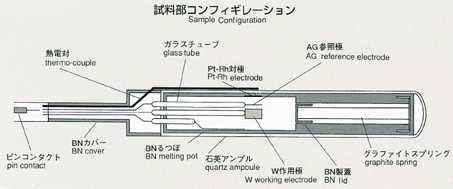

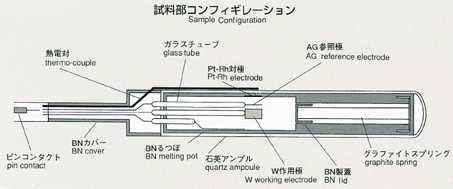

Lithium chloride and potassium are used with silver chloride added as a

tracer, and include electrodes for chronopotentiometry. The samples are

triple-contained (BN-made cylinderCquartz ampouleCtantalum cartridge,from

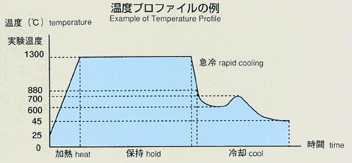

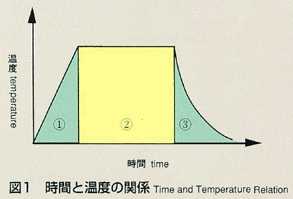

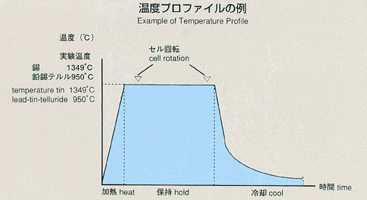

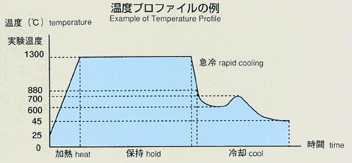

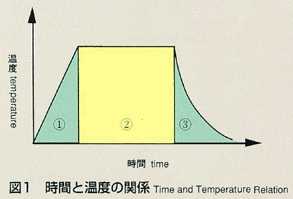

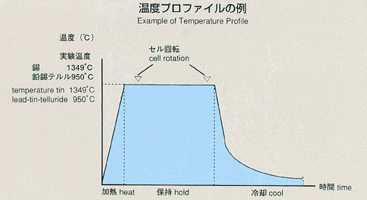

inner to outer). A standard temperature profile is shown below, and parameters

will be changed to cover various types of experiments. Chronopotentiometry

data, obtained through processing of samples, will be sent to the ground

for analysis by researchers.

-

| Ñ | : | Transition

Time |

| Co | : | Initial Concentration |

| n | : | Transfar of electrons |

| A | : | Area of working electorode |

| D | : | Diffusion Coefficient |

| F | : | Faraday

constant |

Measurement of Diffusion Coefficient by Shear Cell Method

Dr.Shinichi Yoda, National Space Development Agency of Japan(NASDA)

1.0bjectives

- An improved long-capillary, shear cell method will be introduced for the

diffusion experiment in MSL-1, and its reliability and mechanism will be

evaluated. Also, the same samples will be processed by the shear cell method

under identical conditions as those experiments using the long-capillary

method, and will be compared and studied together.

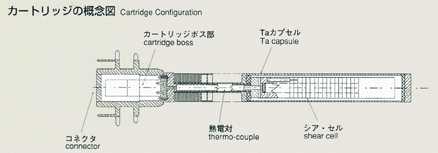

2.Method

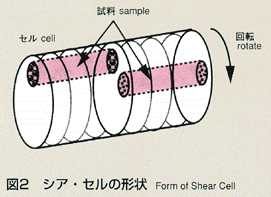

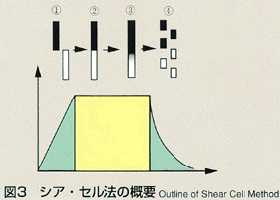

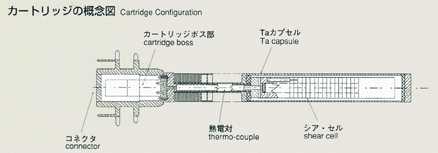

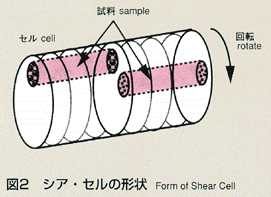

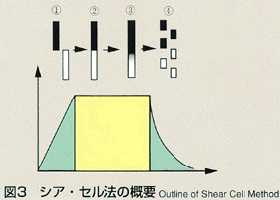

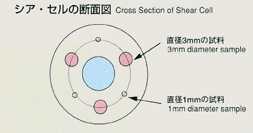

- The shear cell method was conceived to make up for the disadvantage of

the long capillary method. The shear cell melting pot is constructed by

circular segments with a hole, and is capable of engaging and disengaging

the molten samples by rotating the cells. In the shear cell method, the

molten samples will be engaged only while temperature is constant, minimizing

the effect of diffusion during heating and cooling. This method also has

the advantage that it can accurately measure samples which have a large

volume expansion and contraction, or a great difference in melting point.

The disadvantage of the shear cell method is that rotation of cells may

disturb the process of diffusion due to the inertia or viscosity of samples.

The thickness of cell segments and rotation rate, which are critical to

the accuracy, are analyzed and optimized prior to the manufacturing of shear

cells. As a result, the thickness is determined to be 2mm and 28 cell segments

are to be used to construct a melting pot for high accuracy. Two samples,

lead and lead-tin-telluride, will be used, inserted in BN-made melting pots,

and contained in tantalum-made cartridges. The samples will be heated up

to the target temperature and engaged by shear cell rotation done manually

by crew members on orbit. After holding for some duration, the crew will

rotate the cells again to disengage the samples and terminate the diffusion

process. The density distribution of tracer will be examined post mission

using Secondary Ion Mass Spectroscopy (SIMS) and Electron Probe Micro Analyzer

(EPMA) to determine the diffusion coefficient and effects of cell rotation

during the process.

Liquid Phase Sintering

Dr.Randall German, Pennsylvania State University

1.Objectives

-

Sintering is usually used to form materials which have a

high melting point. However, this method requires high temperature and long

duration for heating in order to bond the junctions between ground material

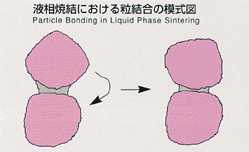

particles by congelation or diffusion. Liquid phase sintering, employed

in MSL-1, makes it possible to process the sintering at lower temperature

and short duration by saturating molten metals, which have lower melting

points, into ground materials. At the junctions between powdered materials

which have high melting points, the effect of interface force is dominant,

promoting the local process of melting and eduction, and bonding between

particles will be accelerated. The existence of high-density particles and

the reaction against gravity disturb particle formation and melt circulation,

resulting in uniform sintering. The mechanism of sintering with respect

to gravity has not been clarified. This experiment is expected to clarify

the mechanism of liquid phase sintering, succeeding from lML-2.

2.Method

- The samples, powdered tungsten, nickel and iron, with seven different

compositions are individually contained in tantalum cartridges and will

be heated up to 1500degrees. Experiments will be performed with various

holding duration of heating.

Diffusion Process in Molten Semiconductors

Dr.David N.Matthiesen, Case Western Reserve University

1.Objectives

- Various types of semiconductors can be made by adding some other elements

to silicon or germanium. The diffusion coefficient of impure elements in

semiconductors is of great importance and critical to manufacturing processes

of good quality. A definitive measurement of diffusion coefficient will

explain the mechanism of diffusion, and high quality semiconductors can

be manufactured. However, an exact diffusion coefficient has not been derived

from ground-based experiments due to the effect of gravity. The samples

of germanium and gallium, with tin and antimony added as impurities, are

used and the diffusion coefficient will be measured using shear cell method

under two different temperature conditions, isothermal and thermogradient.

Also, the effect of the melting pot wall will be investigated by varying

the diameter of samples.

2.Method

- ln MSL-1, NASA-made shear cells will be used to measure the diffusion

coefficient accurately. The mechanism of shear cells is generally the same

as that of the one NASDA developed, which is capable of disengaging and

engaging the samples by rotating the cell segments. The samples with diameter

of 1mm and 3mm are used. The samples will be heated up to the target temperature

and engaged by shear cell rotation done manually by crew members on orbit.

After holding for some duration, the crew will rotate the cells aging to

disengage the samples and the diffusion process will be terminated. The

impurity density will be analyzed, and the diffusion coefficient will be

determined after the mission.

Last Updated : February 18, 1998

![[HOME]](home.gif)

![[INDEX]](index.gif)

![[TOP]](top.gif)