|

| Functional Test of the airlock of Japanese Experiment Module

"Kibo" |

|

A functional test of the airlock

of Japanese Experiment Module "Kibo" was conducted inside the flight

model of Kibo's Pressurized Module (PM) on August 4 and 5, 1999. Here is the report.

(For detail of an airlock see Kibo Structure

-Airlock-. )

| What

is an Airlock Functional Test? |

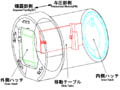

Kibo's airlock is a gateway through which experiment equipment

and other items will be transferred between Kibo's Pressurized Module (PM) and

the Exposed Facility (EF) which is located in space vacuum. The airlock has two

hatches, an inner hatch inside the PM and an outer hatch outside the PM. (See

the figures below.) Neither hatch can be opened unless the other one is closed.

In order to prevent precious air from escaping to space, the air inside the airlock

is recovered into the PM before the outer hatch is opened to transfer the objects.

The test was conducted to confirm that both hatches and the slide table can function

as designed.

|

Airlock |  |  |  |  |

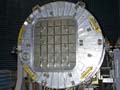

| Airlock location & structure | Outer

Hatch | Inner Hatch |

| Test

Scenes | |  | Hatch

Functional Tests | | | - | | The

outer hatch can be opened and closed electrically, but the inner hatch is operated

by hand. There are two ways to operate the outer hatch electrically, auto mode

and manual mode. The auto mode performs the hatch opening and closing procedures

automatically when a crew member pushes a button. The manual mode is executed

by a crew member confirming each individual step by pushing a button. Also, the

outer hatch is designed to be operated by hand when electric power is not available.

This test confirmed that the hatches can be opened and closed in both modes as

designed.

|

Test Scene | | | The

test scenes below are available.

|

| - |  | Slide

Table Functional Test | | |

| | The slide table is used to

move Orbital Replacement Units (ORUs) and experiment equipment to and from the

PM and EF. It is located inside the airlock. It secures an ORU by latches on both

sides of the table, fixes it in position, then moves. Like the outer hatch, this

slide table can be moved electrically (in both auto mode and manual mode). It

can also be operated by hand when electric power is not available. This test confirmed

that the slide table functions fine in both operational modes.

|

Slide Table |

An ORU being secured | | | The

test scenes below are available.

|

|  | Other

Tests | | | - | | The

inner hatch is operated by hand. The force necessary to open or close the inner

hatch was measured. A seal on the edge of the hatch prevents air leakage from

the gap between the hatch and the airlock wall. When the inner hatch is closed,

the seal fills the gap. Some seal deformation is necessary for the seal to function

normally. The gap was measured to confirm that an appropriate volume for seal

deformation is available.

|

Measuring the force needed to open the hatch by hand. |

| Tests

to follow |

Following this test, a pressurizing and depressurizing

equipment test and a leakage test will be conducted. When ORUs are moved between

the PM and space, the airlock will be depressurized to recover the air. Equipment

for this purpose will be tested in the pressurizing and depressurizing equipment

test. A leakage test will also be conducted to confirm that no air leaks from

the ducts and hatches.

The above two tests will complete the series of

tests conducted for the airlock only. After these two tests are finished, integrated

tests will be conducted in conjunction with other Kibo subsystems.

Last Update:Sep. 29, 1999

|