Summary of Space Shuttle robot arm (Shuttle Remote Manipulator System:

SRMS)

|

Use of Shuttle Robot Arm |

The Shuttle's robot arm is used for various purposes.

- Satellite deployment and retrieval

- Construction of International Space Station

- Transport an EVA crew member at the end of the arm and provide a scaffold

to him or her. (An EVA crew member moves inside the cargo bay in cooperation

with the support crew inside the Shuttle.)

- Survey the outside of the Space Shuttle with a TV camera attached to

the elbow or the wrist of the robot arm.

|

Dimensions |

|

Length

|

45 feet |

|

Diameter

|

15 in |

|

Weight

|

911 lb |

|

Number of joints

|

Six joints (two shoulder joints, one

elbow joint, and three wrist joints) |

|

Max handling capacity

|

266 tons (in space) |

|

Max velocity of end of arm

|

When the arm is not gripping anything

: 60 cm/sec

When the arm is gripping an object : 6 cm/sec |

|

Max rotational speed

|

Approx. 5 degree/sec |

|

Boom material

|

Graphite-epoxy compound |

|

|

|

Shuttle robot arm (SRMS) observed from the aft deck.

|

|

|

| Overview shape of SRMS |

|

SRMS operation |

Robot arm operation (STS-92) |

SRMS is operated inside the Space Shuttle cabin. The operation is performed

from the aft flight deck (AFD), right behind the cockpit, either through

the window or by watching two TV monitors.

To control the SRMS, the operator uses the translational hand controller

(THC) with his or her left hand and manipulates the rotational hand controller

(RHC) with his or her right hand.

Translational hand controller (THC) |

Rotational hand controller (RHC) |

|

How Space Shuttle robot arm grasps objects. |

|

|

End effector of Kibo's manipulator. Same shape as SRMS.

|

How does the Space Shuttle robot arm grasp objects? Many people might think

of human hand or magic hand, but its mechanism is as follows.

At the end of the robot arm is a cylinder called the end effector. Inside

this cylinder equiped three wires that are used to grasp objects. The object

to be grasped needs to have a stick-shaped projection called a grapple

fixture. The three wires in the cylinder fix this grapple fixture at the

center of the cylinder.

However, a sight is needed to acquire the grapple fixture while manipulating

a robot arm as long as 45 feet. The grapple fixture has a target mark,

and a rod is mounted vertically on this mark. The robot arm operator monitors

the TV image of the mark and the rod, and operates the robot arm to approach

the target while keeping the rod standing upright to the robot arm. If

the angular balance between the rod and the robot arm is lost, that can

immediately be detected through the TV image.

Grapple fixture/Target |

End effector and grapple fixture |

-

|

SVS(Space Vision System) |

|

SVS target attached to the Unity module (black round

spots with white backgr

ound) |

The Space Vision System (SVS) is an aid developed by Canada and the US

to precisely measure the location, attitude, and moving rate of objects

in real time by analyzing the TV image of the SVS target.

Several dot patterns on a payload or ISS elements are used as SVS targets.

Three- dimensional fine positions of these targets are measured on the

Earth prior to flight, and the data are referenced for measuring the movement

of the target. Optical characteristics of the TV camera lenses need to

be acquired beforehand as well. SVS information will be displayed on the

monitor graphically and numerically for use of astronauts.

For measurement, at least three SVS targets must be visible and five targets

are preferable. Since distortion due to lighting or thermal conditions

could cause errors, these effects must be minimized.

During Shuttle robot arm (SRMS) or the International Space Station (ISS)

robot arm (SSRMS) operations to assemble the ISS, SVS will be a necessary

technology used in combination with TV camera images when the operator

can't directly(note) see the objects to be manipulateed.

Note. Before the ISS assembly began, Shuttle robot arm operations were

performed by a crew member watching the manipulated objects through the

Shuttle window.

|

Robot arm operation mode |

The robot arm can be operated by Space Shuttle crew members. However, automatic

mode, in which the robot arm moves automatically along a trajectory computed

on the Earth is also possible. There is also another mode in which single

joint can be driven. These methods are selected to suite the needs of the

operation.

|

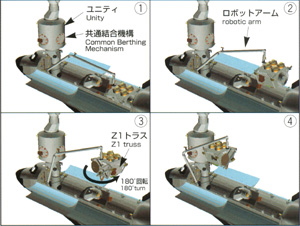

Procedure for installing the Z1 truss using the robotic arm |

|

|

Procedure for installing the Z1 truss using the robotic

arm

|

First, using the Shuttle's robotic arm, grapple the Z1 truss which is anchored

to the cargo bay. Next, operate to release the latches which are holding

the Z1 truss in the cargo bay, then unberth the Z1 truss.

Manipulate the robotic arm while observing the camera image on the TV monitor

installed on the operation console, then slowly maneuver the Z1 truss toward

Unity.

Turn the Z1 truss 180 degrees in order to bring the side to be connected

into line with Unity.

After bringing the Z1 truss to a point about 60 cm from Unity, use the

Space Vision System (SVS) to continue to move the Z1 truss accurately toward

the connecting point with Unity. Using the capture latch, temporarily connect

the Z1 truss to the Common Berthing Mechanism (CBM) of Unity, then send

an instruction from the Shuttle to install the Z1 truss to Unity using

the 16 drive bolts inside the CBM. This will be the first attempt to conduct

connecting of ISS modules in space by using a CBM.

|

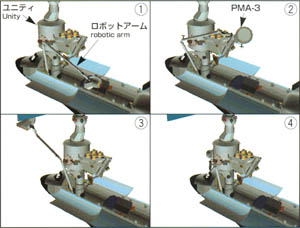

PMA-3 installation procedure using the robotic arm |

|

|

Procedure for installing the Z1 truss using the robotic

arm

|

The procedure for installing PMA-3 is basically the same as that for the

Z1 truss. At first the EVA crew members will release the bolts that fasten

the PMA-3 to the cargo bay.

Then Astronaut Wakata will unberth the PMA-3 from the cargo bay and maneuver

it to Unity by using the robotic arm. The same way as the Z1 truss, PMA-3

will be installed to Unity by using the position and attitude information

of the Space Vision System, while the EVA crew members will observe the

operations.

|